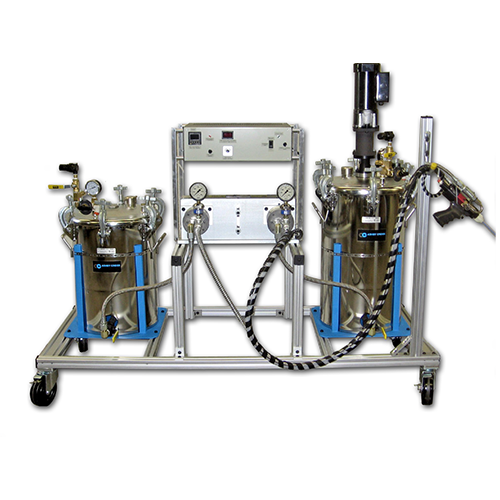

3800 SA

The 3800 Series Single Acting dispensing system is a high throughput system for abrasive adhesives up to 1500 cc/stroke.

Read more

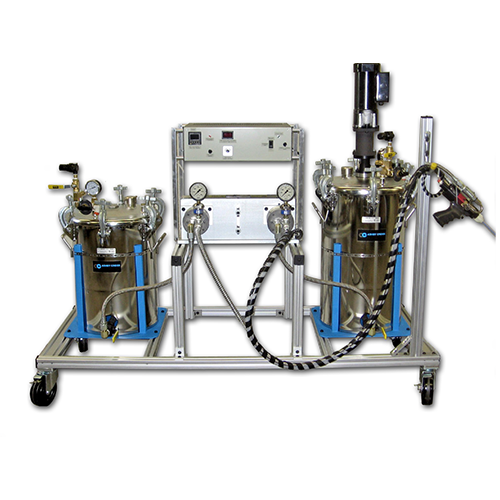

2500 SA

For production Potting, Encapsulating, Molding, or Central Filling of 2-part Reactive Formulations with Abrasive Filters which settle out of suspension.

Read more

2500 DA w/Drive Assist

The pneumatic Drive Assist cylinder increases the unit’s capability in processing high viscosity materials.

Read more

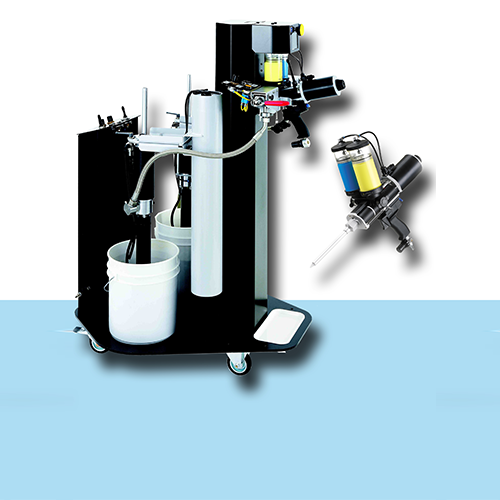

DXBG

Ideal for use with epoxy, silicone, urethane and acrylic, this machine features easy-to-fill 2-gallon reservoirs.

Read more

AC125

The AC125 adhesive dispensing system is designed with high quality and low up front cost in mind.

Read more

1125VR

The 1125 Variable Ratio is a piston and cylinder meter mix machine used for light or mid volume production potting applications.

Read more

ACCI Dual Dispenser Series

Combines the simplicity and versatility of the dual barrel cartridge with bench mount support.

Read more

400 mL Hand Dispenser

Rechargeable/Barry Operated hand dispenser.

Read more

GP80

The GP-80 is a bench-top, adjustable ratio, meter, mix system for dispensing pourable, 2-part materials.

Read more

Dynastat®

Model 6000 DYNA-STAT® combines complete dynamic mixing with disposable mix chambers

Read more

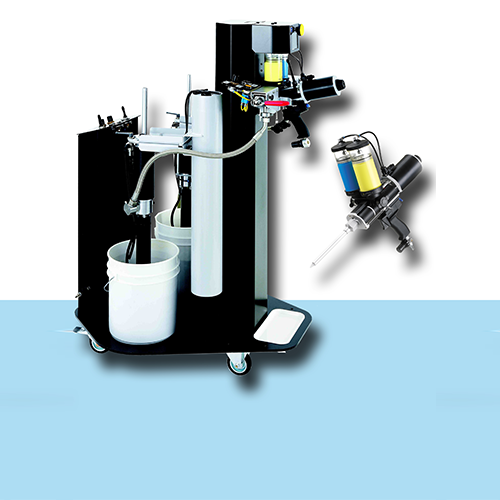

DXR Refill Station

The DXR Refill Station and DXH Dispenser are ideal tools for bonding applications needing mobility and multiple operators.

Read more

GPFR 1000

Rapid-Pro Series Resin Processing System for 2-component reactive materials.

Read more

One Part Dispensing

From applications that require small, precision dispensing to ones that need large quantities of single component epoxies and adhesives, Ashby Cross has the right equipment for you.

Read more

IDS

Intelligent Dispensing Module may be added to many of the Ashby Cross Systems. PLC with HMI for complete system control

Read more